- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

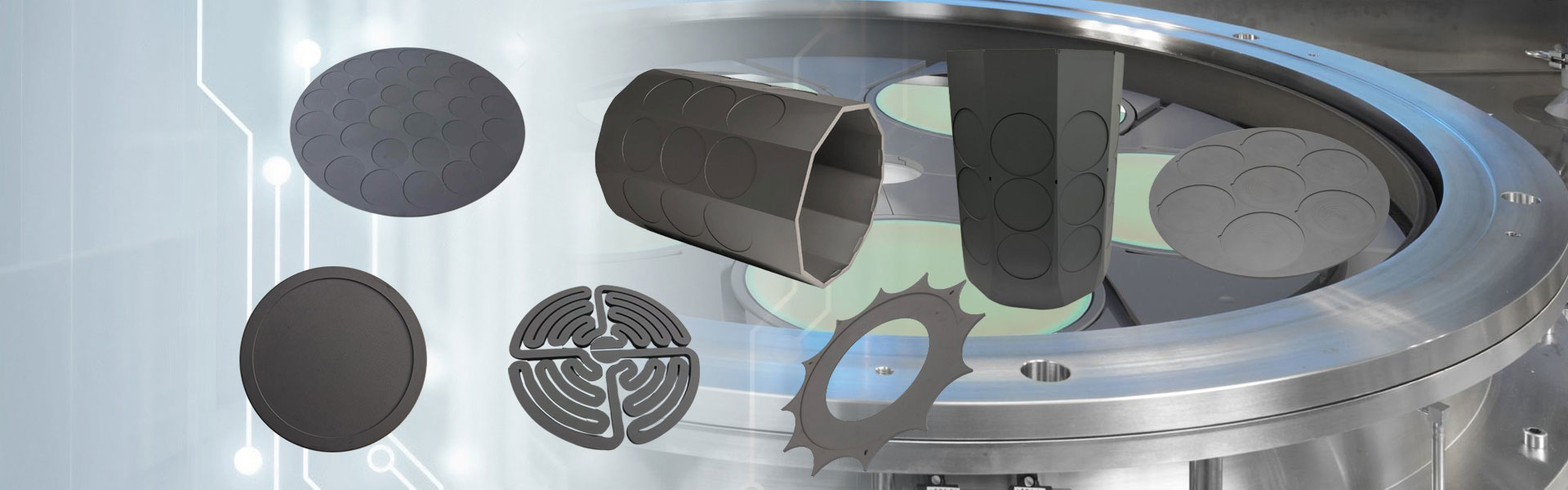

CVD Tac iactaret annulos

High-perficientur semicorex cvd Tac fluxus Guide Components in crystallum incrementum Furnaces ad curare precise Gas control et scelerisque stabilitatem. Semicoreex offert unammatched qualitas, ipsum peritia, et proven perficientur in maxime postulat semiconductor environments. *

Mitte Inquisitionem

Tac Tac iactaret anulos sunt praecisione, predictas, predictae, ad crystallum incrementum processus, praecipue in directional solidificatione et czochralski (CZ) trahens systems. Hae CVD Tac iactaret anulos function ut fluxus duce components-communiter referred to as "fluxus Rector Annulorum" vel "Gas deflectionum annulos et Gas fluxus patterns et scelerisque environments in cristallum incrementum tempus.

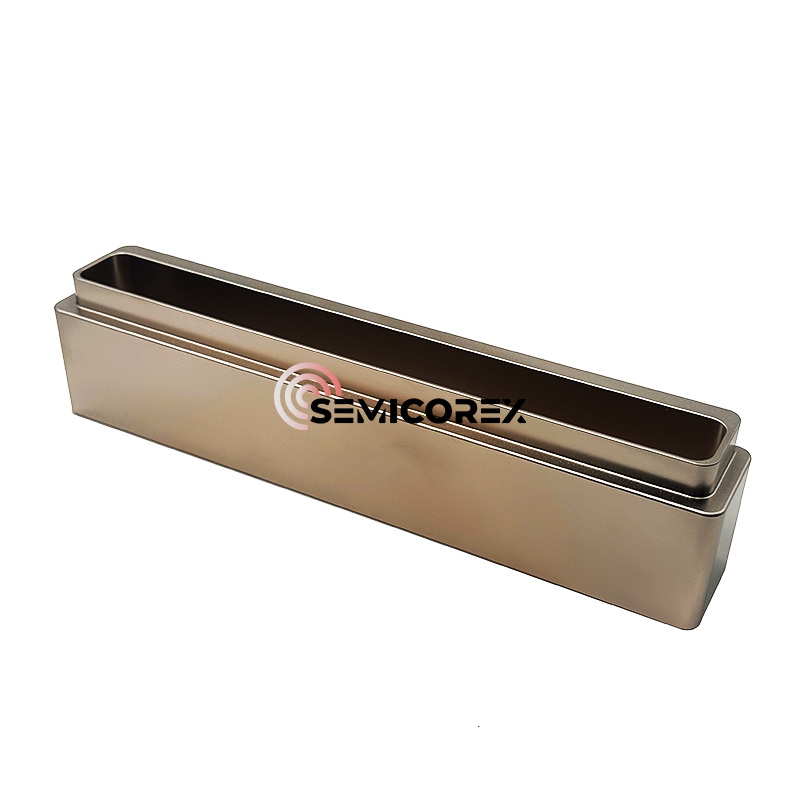

Taking Silicon Carbide Wafer incrementum ut exemplum, graphite materiae et ipsum, ipsum compositum materiae in scelerisque agro materiae sunt difficile ad occursum in universa atmosphaera (si, sic₂, sizc) processus ad MMCCC ℃. Non solum est ministerium brevis, diversis locis reponuntur unusquisque decem Furnorum et dialysis et volatilizatione graphite ad altum temperaturis facile ducere cristallum defectus ut ipsum inclusions. In order to ensure the high quality and stable growth of semiconductor crystals, and considering the cost of industrial production, ultra-high temperature corrosion-resistant ceramic coatings are prepared on the surface of graphite parts, which will extend the life of graphite components, inhibit impurity migration and improve crystal purity. In epitaxial incrementum de Silicon carbide, Silicon carbide iactaret graphite susceptoribus plerumque solebant ferre et calor unum crystallum subiecta. Servitium vitae adhuc opus est melius, et silicon carbide deposits in interface opus est purgari semper. Contra:Tantalum Carbide (Tac) coatingsSunt plus repugnant ad corrosivum atmosphaerae et altum temperaturis, et core technology pro huiusmodi sic crystallis ad "crescere, crescere densissima et crescere bene."

Tac habet liquescens punctum usque ad MMMDCCCLXXX ℃ et habet altum mechanica vires, duritiam et scelerisque inpulsa resistentia; Hoc est bonum chemical inertness et scelerisque stabilitatem ad ammoniacus, hydrogenii, et Silicon-continet vapor ad altum temperaturis. Graphite (Carbon-Carbon compositum) materiae iactat cum Tac coatings sunt valde verisimile reponere traditional summus puritate graphite, PBN, in agro Aerospace, Tac-oxidation et anti-ablationem, et habet lata application et anti-ablationem, et lata application ad esse, et in ASTALL ABLATIONUM, et lata application ad esse, quod est in altum, et lata application ad esse, et in aemulantur, et in ADSPERSIGNITIS ADSUGS, et lata application ad esse, et in ADSPERSIGNITIS ADSTALITIS, et lata application in ASTALIPS, et lata application in ASTALLIGING. Tamen, illic es adhuc plures provocationes ad consequi praeparatio densa, uniformis, et non-tio Tac coatings super superficiem graphite et promovere industriae massa productio. In hoc processus explorans tutela mechanism de coating, innovating productio processus, et competing cum summo aliena campester sunt crucial ad tertiam generationem semiconductor crystallum incrementum et epitaxy.

In Sic Pvt processus usura a paro of conventional graphite etCVD Tac iactaretAnnulos est exemplar ad intelligere effectus emissivity in temperatus distribution, quae ducunt ad mutationes in incrementum rate et ingot figura. Ostenditur quod CVD Tac tunicas annulos consequi magis uniformis temperaturis comparari existentium Graphite. Praeterea, optimum scelerisque et eget stabilitatem de Tac coating prohibet reactionem de carboni cum vapor. Ut effectus, in Tac coating facit distribution of C / si in radiale directionem magis uniformis.