- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Rica

Sermicorex Rector CVD Tantalum carbide coating est valde certa et provectus component quia sic una crystallum incrementum Furnorum. Superior materia proprietatibus, diuturnitatem, et praecisione-machinatrix consilio facere quod essentia pars crystalli incrementum processus. Per eligens nostri altus-qualitas dux anulus, manufacturers potest consequi auctus processum stabilitatem, altius cedere rates et superior sic crystallum qualitas. *

Mitte Inquisitionem

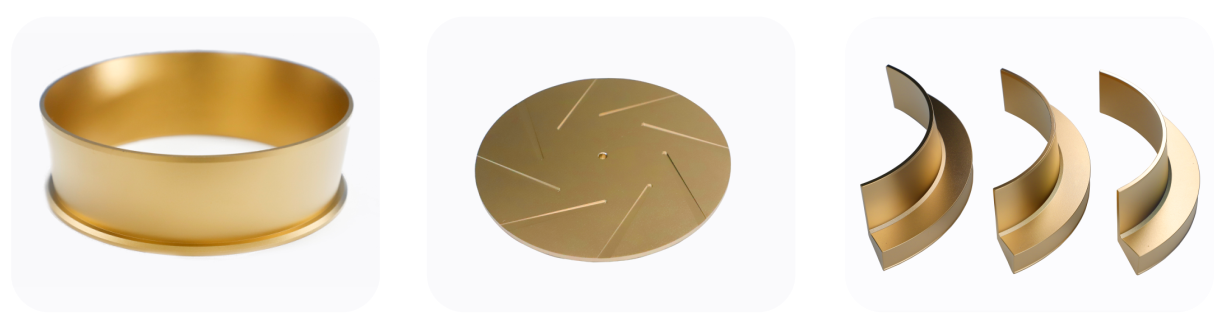

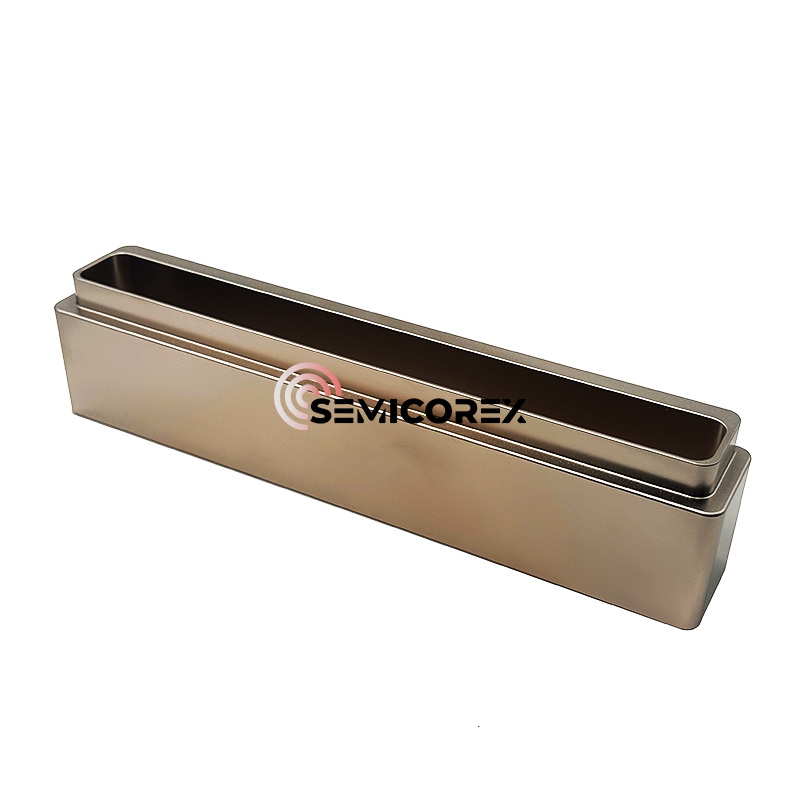

Semicorex dux anulum est a crucial component in Sic (Silicon carbide) unum crystallum incrementum caminus, disposito ad optimize crystallum incrementum environment. Hoc princeps-perficientur duce anulus est fabricari a summus puritas graphite et features a re publica-of-arte CVD (eget vapor depositione)Tantalum carbide (Tac) coating. Coniunctio harum materiae ensures superiorem diuturnitatem, scelerisque stabilitatem et resistentia ad extremum eget et corporalis conditionibus.

Materia et coating

In basi materia de dux anulus est summus puritas graphite, electi pro sua optimum scelerisque conductivity, mechanica vires et stabilitatem ad altum temperaturis. In graphite subiectum est ergo iactaret cum densa, uniformis laminum Tantalum carbide usura an provectus CVD processus. Tantalum Carbide est bene notum est eius eximia duritia, oxidatio resistentia, et eget inertness, faciens idealis tutela iacuit pro graphite components operating in dura environments.

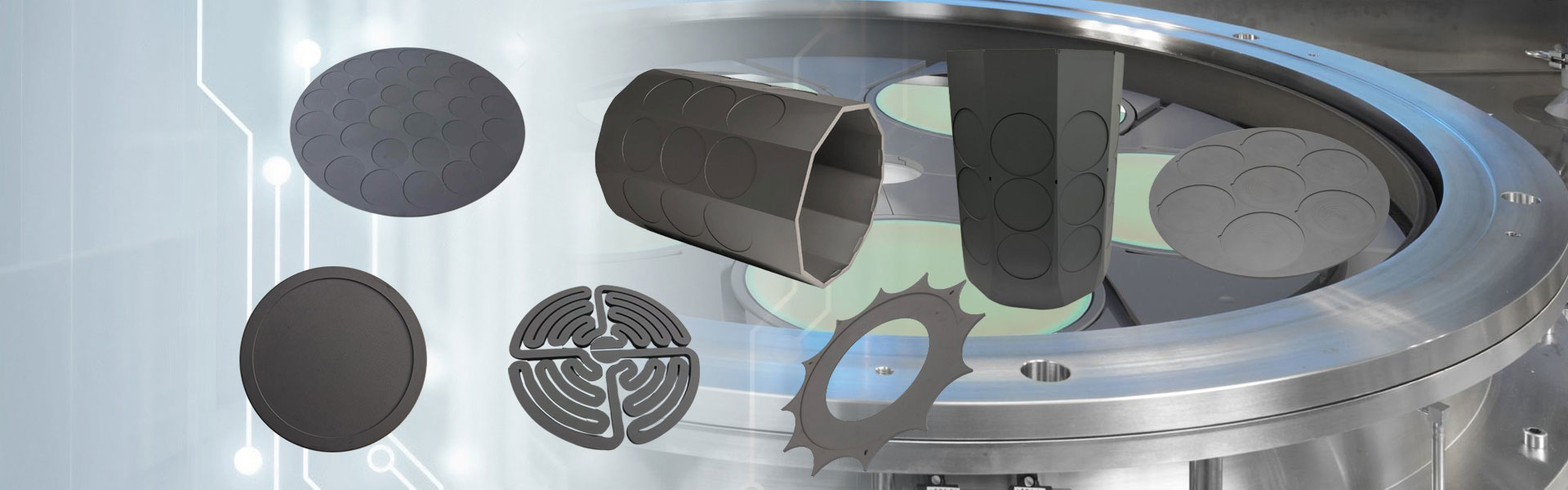

The third generation wide bandgap semiconductor materials represented by gallium nitride (GaN) and silicon carbide (SiC) have excellent photoelectric conversion and microwave signal transmission capabilities, and can meet the needs of high-frequency, high-temperature, high-power and radiation-resistant electronic devices. Ideo non habent lata application spes in agros novae generationis mobilis communications, novum industria vehicles, dolor grids et leucit. In comprehensive progressionem tertia generatione semiconductor industria torquem instanter requirit breakthroughs in key core technologies, continuum incrementum consilio et innovation, et resolutio important dependentia.

Taking Silicon Carbide Wafer incrementum ut exemplum, graphite materiae et ipsum, ipsum compositum materiae in scelerisque agro materiae sunt difficile ad occursum in universa atmosphaera (si, sic₂, sizc) processus ad MMCCC ℃. Non solum est ministerium brevis, diversis locis reponuntur unusquisque ad decem Furnorum et infiltration et volatilizatione graphite ad altum temperaturis facile ad cristallum defectus ut ipsum inclusions. In order to ensure the high quality and stable growth of semiconductor crystals, and considering the cost of industrial production, ultra-high temperature corrosion-resistant ceramic coatings are prepared on the surface of graphite parts, which will extend the life of graphite components, inhibit impurity migration and improve crystal purity. In epitaxial incrementum de Silicon carbide, a silicon carbide iactaret graphite susceptator est plerumque solebat sustinere et calor unum crystallum subiectum. Et ministerium vitae adhuc indiget ut melius, et siliconium carbide deposits in interface postulo ut purgari semper. Contra:Tantalum carbide (Tac) coatingEst plus repugnant ad corrosivum atmosphaera et altum temperatus, et est core technology ad "incrementum, crassitudine, et qualis" talis sic crystallis.

Cum SIC paratus a corporalis vapor onerariis (Pvt), in semen crystallum est in relative humilis temperatus zonam et sic rudis materia est in relative caliditas zonam (supra MMCD ℃). The raw material decomposes to produce SiXCy (mainly containing Si, SiC₂, Si₂C, etc.), and the gas phase material is transported from the high temperature zone to the seed crystal in the low temperature zone, and nucleates and grows to form a single crystal. Et calor ager materials in hoc processum, ut cruciatur, dux anulus, et semen crystal possessor, oportet repugnant ad altum temperaturis et non contaminare in sic rudis materia et sic una crystallum. SIC et aln paratus per Tac-iactaret Graphite scelerisque agro materiae sunt lautus, cum fere nulla impudicitiis ut carbonis (oxygeni, NITROGENIUM), paucioribus et defectus, minor resistentia etcer et significantly (post koh etching et in quolibet in densitate (post koh etching et in quolibet et significantie (post Koh etching), magna improvans qualis est in cristallum. Praeterea, in pondus damnum rate de Tac cruce est fere nulla, species est integrum, et potest esse recycled, quod potest amplio sustineri et efficientiam tali crystallo praeparatione.