- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Sinae Isostatic Graphite Manufacturers, Suppliers, Factory

- View as

Graphite Paul

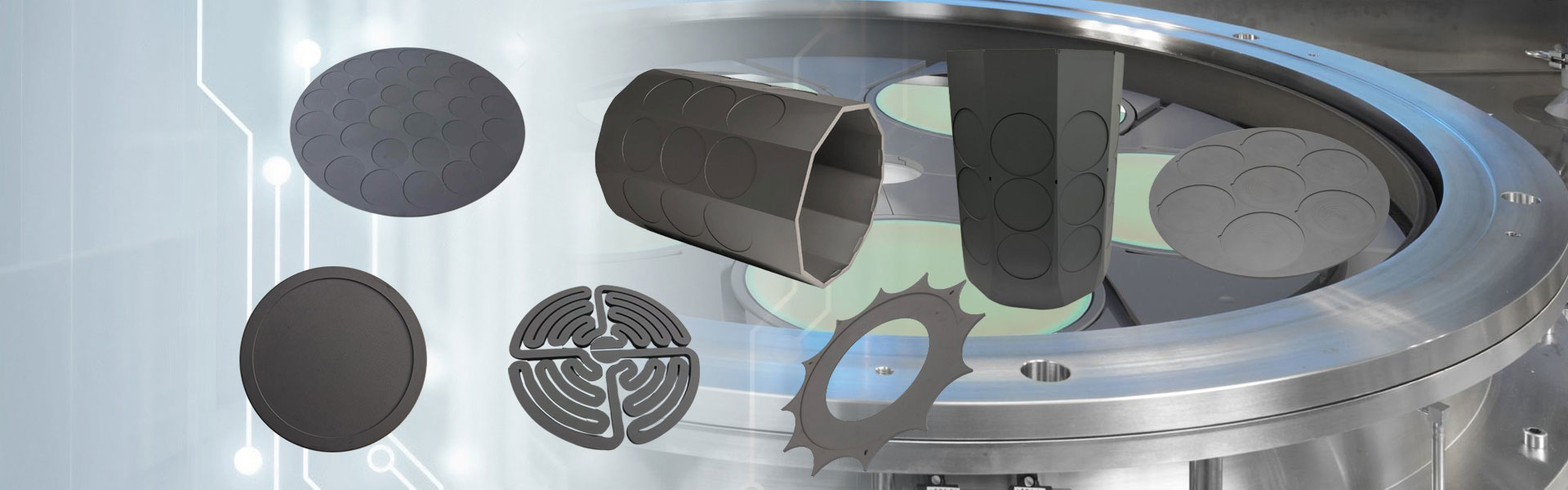

Semicorex GALCK Peccator est a crucial component in Polysilicon vestibulum, late in solis industria. Ut in demanda ad altus-puritas Silicon Wafers augetur, opus est summus perficientur processus tools ut graphite chucks facta essential. Product a summus puritas specialitate Graphite nostri Graphite chucks disposito resistere extrema temperaturis, eget nuditate et mechanica passiones dum maintaining dimensiva stabilitatem. *

Lege plusMitte InquisitionemGraphite Rotor et Shaft

Congregatio rotor semicorex graphita et harundo partes cruciales sunt, quae plerumque ad depravationem in aluminii et aluminii commixtionibus excoquunt.

Lege plusMitte InquisitionemGraphite æstus scutum

Ut efficaciam processus in duris ambitibus efficiat, Semicorex Graphite Calidi clypei fiunt cum materiarum graphitarum premium et acumen fabricandi technologiae.

Lege plusMitte InquisitionemGraphite Calefaciens Industrial Element

Semicorex graphite calefactio industriae elementum est unum e maximis partibus fornacibus sintering vacuum summus temperaturae. Essentiale est propter varias processus scelerisque processuum propter earum qualitates materiales sophisticatas.

Lege plusMitte InquisitionemGraphite Bushing

Semicorex Graphite Bushing, cum suis singularibus materialibus notis et aptabilitate, munus criticum agit in perficiendo et longivitate systematum mechanicorum augendo, suam significationem in hodiernis machinandis et fabricandis processibus percipiendo.

Lege plusMitte InquisitionemGraphite Ring

Semicorex Graphite Ringi facultates extremas condiciones et facilitatem institutionis sustinendi fac illis necessariam componentem in industriis ut hydraulicis, pneumaticis, et caloribus commutatoribus.

Lege plusMitte Inquisitionem