- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

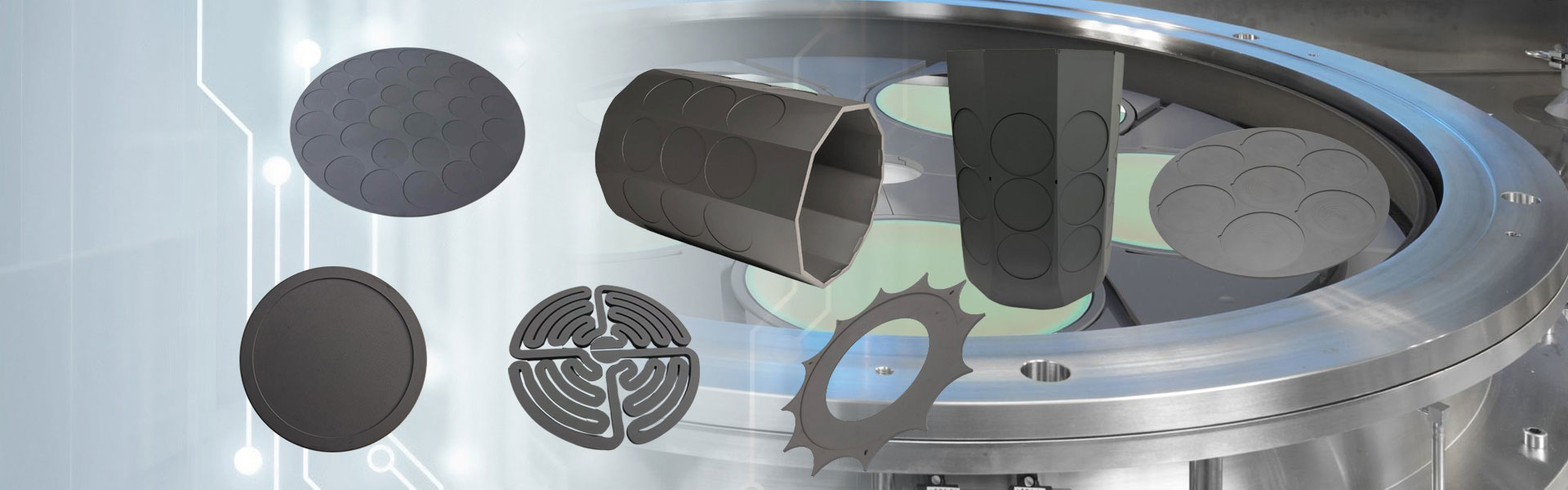

Etching Wafer Carrier

Semicoreex Etching Wafer Carrier cum CVD sic coating est provectus, summus perficientur solutio tailored ad postulans semiconductor etching applications. Superioris scelerisque stabilitatem, chemical resistentia, et mechanica diuturnitatem facere quod essentiale component in modern wafer fabricam, cursus summus efficientiam, reliabiling worldwide et efficaciam pro semiconductor manufacturers Worldwide. *

Mitte Inquisitionem

Semicoreex Etching Wafer Portitorem est summus perficientur substrati firmamentum suggestu disposito pro semiconductor fabricatione processuum, specie in laganum etching applications. Engineered cum summus puritas graphite basi et iactaret cum eget vapor depositione (cvd) Silicon carbide (sic), hoc wafer carrier providet eximia chemical resistentia, scelerisque stabilitatem, et mechanica etching environments.

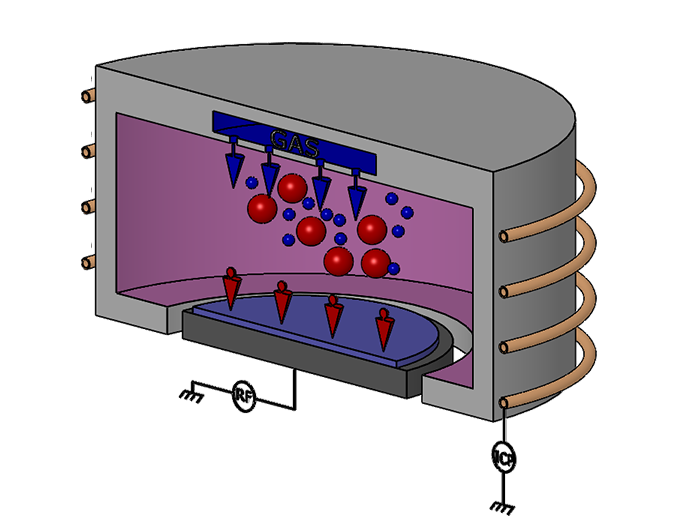

Et Etching laga carrier est iactaret cum uniformis cvd sic iacuit, quod significantly enhances eius eget resistentia contra infestantibus plasma et mordax vapores in Etching processus. CVD est pelagus technology ad parat sic coating in subiecto superficiem praesenti. Pelagus processus est quod Gas phase Reactant rudis materiae subeunt seriem corporis et eget reactiones in subiecto superficie, et postremo depositum in subiecto superficies parare sic coating. In sic coating paravit CVD technology est propinqua ad subiectum superficiem, quae potest efficaciter amplio oxidatio resistentia et ablationem resistentia substantiae materiae, sed depositionem tempus talis est longa et reactionem continet quandam toxicus gases.

CVD Silicon carbide coatingPartes sunt late in Etching apparatu, Mocvd Equipment, si epitaxial apparatu et sic epitaxial apparatu, celeri scelerisque processus apparatu et aliis agris. Altiore, maxima Market Segmentum CVD Silicon Carbide coating partibus sit etching apparatu et epitaxial apparatu partium. Ob humilis reactivity et conductivity CVD Silicon carbide coating ad CHLORUM, quibus et fluorine fluorine-quibus etching vapores, quod fit idealis materiam ad focusing annulos et aliis partibus plasma etching apparatu.CVD sic partesIn Etching apparatu includitfocusing annulos, Gas imber capitibus, Scrutat,ora annulos, Etc accipiat focus anulum ut exemplum. Et focus anulus est magna pars positus extra laganum et in directum contactus cum lagae. Voltage applicantur ad anulum ad focus ad plasma transiens per circulum, ita focusing ad plasma in laganum ad amplio dispensando uniformitatem. Traditional Focus annulos fiunt ex Silicon aut quartz. Cum progressionis in integrated circuitu Miniaturization, in demanda et momenti etching processibus in integrated circuitu vestibulum sunt augendae, et virtute et industria etching Pure permanere crescat.

In sicco coating offert superior resistentia contra fluorine-fundatur (f₂) et CHLORUM-fundatur (Cl₂) Plasma Etching Chemistries, ne Degradation et maintaining structural integritas super diuturna usus. Hoc chemical robustness ensures consistent perficientur et reduces contaminationem metus durante laganum processus. Et laga carrier potest esse tailored ad varias laganum magnitudinum (E.G., 200mm, 300mm) et specifica etching ratio requisita. Custom Slote Designs et foraminis exemplaria sunt praesto ad optimize laga positus, Gas fluxus imperium, et processum efficientiam.

Applications et beneficia

Et Etching Wafer Portitorem est praesertim in semiconductor vestibulum ad siccis etching processus, inter Plasma Etching (PE), Reactive Ion Etching (Rie) et profunda Reactive Ion Etching (Drie). Est late adopted in productione integrated circuits (ICS), mems cogitationes, potentia electronics et compositis semiconductor wafers. Et robust sic coating ensures consistent etching praecessi a ne materia degradation. Et compositum de Graphite et sic Long-term diuturnitatem, reducing sustentacionem et postea costs. Et lenis et densa sic superficiem minimizes particula generationem, cursus princeps laganum cede et superior fabrica perficientur. Exceptionalibus resistentia ad dura etching environments reduces opus crebris replacements, improving vestibulum efficientiam.