- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Quam Advanced Materials solve III Critical provocationes in semiconductor fornacem Design

2025-02-12

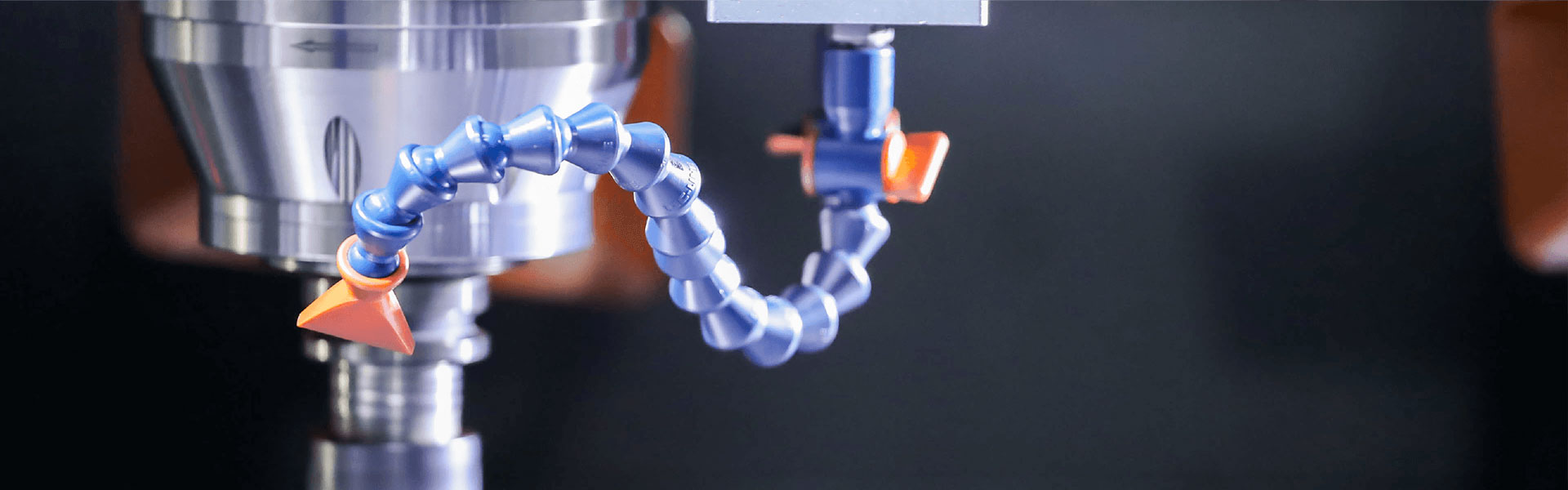

Genus ad shrink Transistor magnitudinum et scale solaris cellula efficientiam est propellentibus scelerisque processus apparatu ad terminum. In semicorex, Diximus duos decennia collaborating cum ducens semiconductor et PV fabrica ut oratio a recurrens dolor punctum, cum vexillum materiae deficient in extrema condiciones, totum productio batches potest esse in extremo conditionibus, tota productio potest esse in extrema conditiones, tota productio potest esse inest.

CVD coatings: Armor ad processum components

Chemical vapor depositione (CVD), sicut Silicon Carbide (sic) et Tantalum Carbide (Tac) sunt revolutionizing component Vivacitas in dura environments:

Sic coatingCommoda:

Resistat temperaturis ad 1,650 ° C in inertem atmosphaerae

Reduces particula contagiatori in epitaxial incrementum reactors

Se extendit ministerium vitae graphite susceptos per 3-5x

Tac coatingIn Diffusio claustra:

Perspicuum Furoris Silicon Infiltration in Cruciblem (99,999% puritas retention)

Minimizes Wafer Warpage in celeri scelerisque Processing (RTP)

![]()

Cum temperaturis superare MDC ° C, in CVD coating utilitatem

Hoc non magicae - suus 'materiae scientia. Proprietatis CVD processus deposits tam sic et Tac coatings cum nuclei gradu praecisione creando superficies;

Silicon Vapor Corrosio PRAECIPIO PRAETERITUS 3X longior quam vexillum coatings

Ponere <0.5μm crassitie variation trans universa geometries

Eliminate coating delaination etiam sub scelerisque cycling

Et tacet discrimine in scelerisque uniformitatem

In crystallum incrementum Furnaces, repugnans temperatus distribution potest conversus a $ 250K Silicon ingot in exiguo. Per materiam innovations sicut:

Density-gradus graphite sensit (0.18-0.25g / CM³ gradiente consilio)

Carbon-Carbon Composita Insulators cum

... Weve adiuvisti clients consequi: ✔ ✔ ± 1.5 ° Cx axial temperatus uniformitas in 300mm czochralski systems ✔ ✔ XL% Faster refrigerationem rates sine ingot crepuit

Quid Vicus Puritas rebus plus quam semper

Cum autem Tener-I Mems Fundry investigari particula defectus ad eorum etching cubiculum liners nostri bulla, liberum fused quartz solution: Reducitur metallum contagione a LXXXIX% (ICP, MS Analysis) Extended Praecaventur sustentationem intervals ex III ad VIII mensibus Achieved 99,999% initial puritate cum <0.1IPPB Alkali Metal Content

Quam Specifications: Application Engineering rebus Dum technical Specs providere baseline comparationes, realis-mundi perficientur pendeat: • Material-Processus coupling - Quid components penitus cum specifica chemistries (E.G., Cl₂ vs. Sf₆ Plaesmas) • Defectum Mode Libraries - Nostrum database of 1,200+ pars defectum cases informat materiam lectio • Custom gradatim - adjusting Graphite Porosity / conductivity per partem crucem-sectiones

High-qualitas offert semicorexTantalum carbide iactaretetSilicon carbide iactaretcustomized partes. Si vos have ullus inquisitione aut opus additional details, placere non dubitant ad adepto in tactus nobiscum.

Contact Phone # + 86-13567891907

Email: Sales@Sicorex.com