- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Quid sunt applications de Silicon Carbide Ceramic membranas

2025-02-21

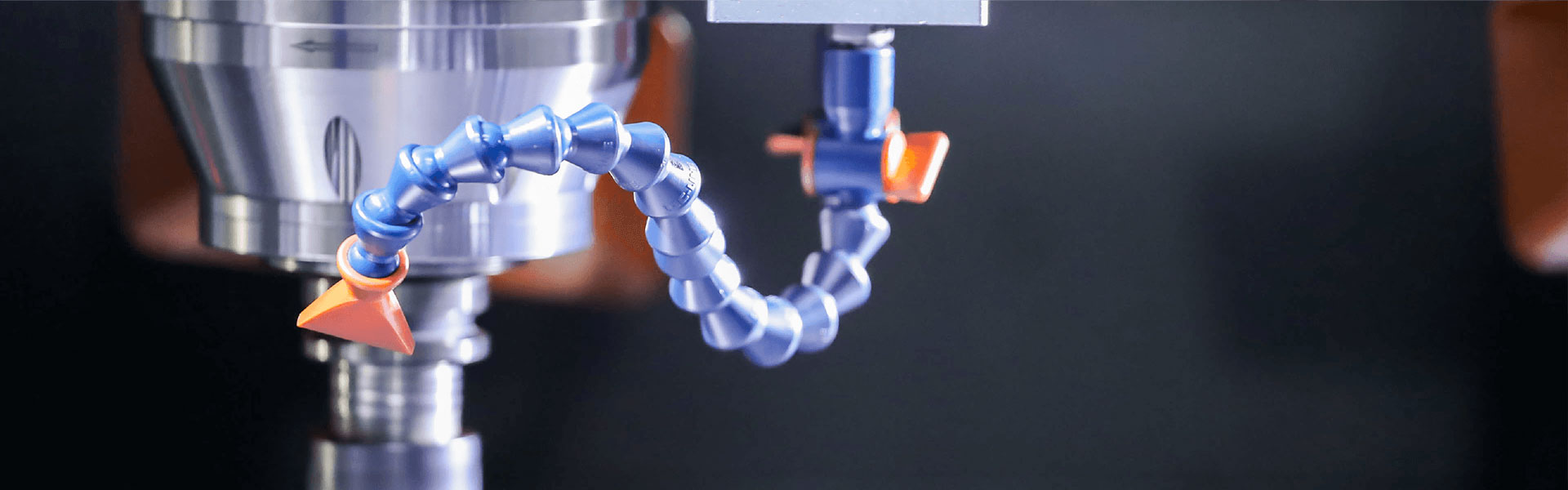

Silicon Carbide Ceramic membranashabere significant commoda in agros aquae curatio et industriae separationis, et applicationem missionibus sunt lata-vndique. Et sequenti systematice describitur eorum technica characteres et applications in altus-temperatus flue Gas purificationis, oleum-aquae separationem, et Gas separationem in tandem coniunctim afficiens cum tardus Research Results:

I. High-Temperature Flue Gas Purificacionis

Silicon carbide Ceramic membranae facti sunt specimen materiae ad summus temperatus Gas Purificacionis Ob eorum summus temperatus resistentia (usque ad DCCC ° c), scelerisque inpulsa resistentia et eget inertness. Et efficiently remove particulata materia ut PM2.5 per pore protegendo et superficiem adsorption machinationes et late in altum temperatus flue Gas curatio in calculo eget, Polysilicon et ferro industries. Exempli gratia, in activated Coke Desulfurization Processus in Cingking Industry, Silicon Carbide Membranae non solum consequi particula retentione rate de XCIX%, sed etiam auget in specifica superficiem in pore remotionem technology, onus, et eodem tempore, et in sustulat operationem, et sustentacionem costs.

II. Oleum-aqua separationem

Silicon carbide membranas praestare bene in curatio de oleum wastewater. Core commoda sunt:

High fluxus: Dynamic membrana regeneratio technology facit aquam fluxus 3-4 temporibus traditional Ceramic membranis. Exempli gratia, cum ageretur oilfield produci aquam, in fluxus potest pervenire CCCVI l / (m² · h) (transmembrane pressura differentia 0,5 bar) et fluuium recuperare rate post backwashing excedit XCV%.

Fortis hydrophilicity: et contactus angulus cum aqua est solum 0.3 °, et oleum droplets (including emulsified oleum) sunt efficaciter intercepta per electrostatic repulsas, et oleum aqua separationis efficientiam pervenit 93.3%.

ROSIO resistentia: Non potest sustinere PH 0-14 environment, idoneam fortis acidum / alkali wastewater curatio ut petrochemical, printing et tydeing, et membrana plus quam X annis.

Typical casibus ostendere quod cum Silicon carbide membrana bioreactor (MBR) adhibetur pro oleum wastewater curatio, quod est aucbidity est

III. Gas separationem

Silicon carbide membranasHabere electionem electionis applicationem characteres in agro Gas separationem:

Hydrogenii Recuperatio: Asymmetrric structuram membranas consequi H₂ / Ch₄ separationem coefficientem magis quam L per Moderni inconveniens effectus, quod est idoneam ad hydrogenium extractionem ex cauda est in Refineries, et industria exacta est a LX% comparari cum traditional Psa.

Gas-solidum Separationem: favum Silicon carbide membrana Filtra potest eodem tempore processus altus-caliditas (

Technical limitations: at praesens, in pore magnitudinem densa silicon carbide membranas est maxime intentum ad Microfiltration campester (40nm-10μm) et separationem efficientiam parva mocularicis talis ut co ^ / n₂ est limited. Necesse est parare sub-nanometer separationem iacuit per CVD ad expand application.

IV. Technology Development Trends

Innovation in praeparatione technology est clavis directionem:

Low cost: The particle stacking method combined with low-temperature sintering aids (such as aluminosilicates) can reduce the sintering temperature from 1600°C to 1000°C, and the porosity can be adjusted to 35%-42%, taking into account both performance and cost.

Multifunctionality: et membrana est praeditus photocatalytic et antibacterial proprietatibus per superficiem insitionis (ut sio₂ coating) vel doping (ut tio₂) ad consequi synergistic degradamentum pollutants.

In summary, Silicon carbide Ceramic membranae, cum maxima environmental adaptability et modularis consilio, sunt driving aquam curatio et industriae separationem technologiae in altum efficientiam et humilis carbonis et magni potentia in agro et in futurum.

High-qualitas offert semicorexSilicon carbide membranas. Si vos have ullus inquisitione aut opus additional details, placere non dubitant ad adepto in tactus nobiscum.

Contact Phone # + 86-13567891907

Email: Sales@Sicorex.com