- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

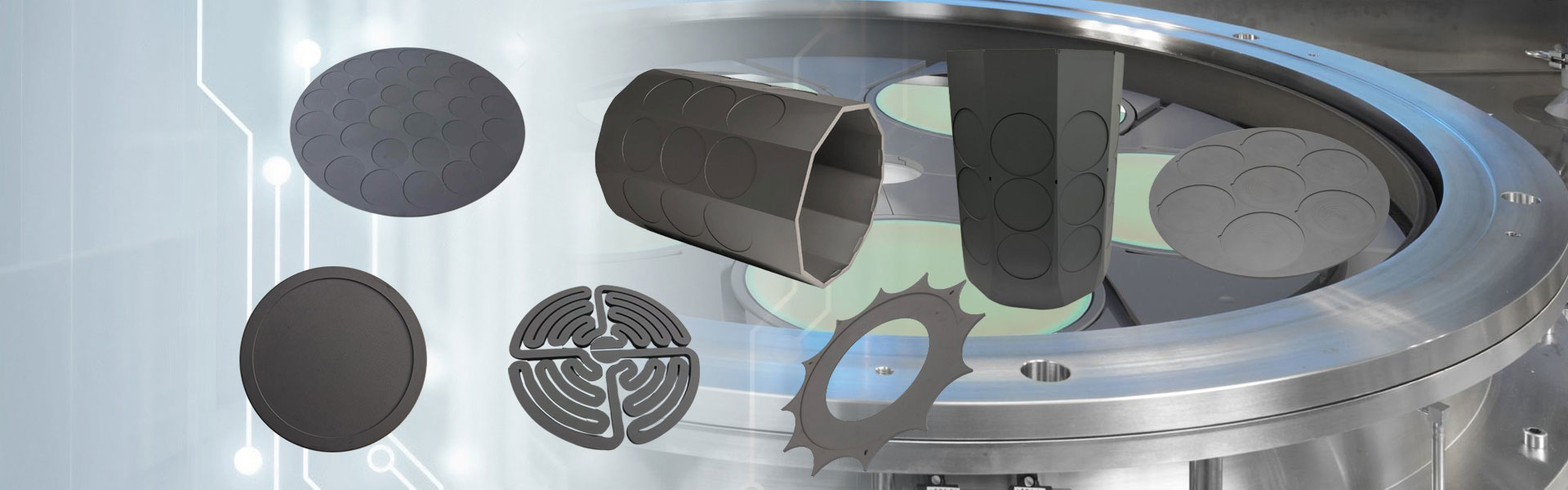

IV-inch sic naves

SIC navibus altus-perficientur altus-IV-inch laminis in altum perficientur laganum et chemical stabilitatem in semiconductor vestibulum. Spera in industria principes, semicorex combines provectus materiae peritia cum praecisione Engineering ut eripere products quod augendae cede, reliability et operational efficientiam. *

Mitte Inquisitionem

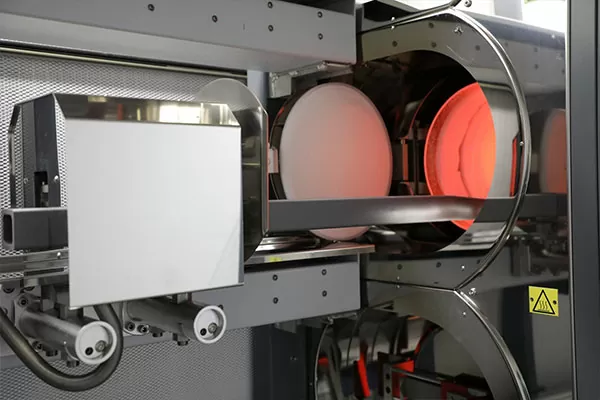

Semicoreex IV-inch Sic naves sunt machinator obviam postulantes requisitis modern semiconductor vestibulum processus, praecipue in summus temperatus et mordrosive environments. Constructum praecisione a summo puritateSic materialesHae naves offerre eximia scelerisque stabilitatem, mechanica vires, et eget resistentia, faciens ea specimen ad tutum pertractatio et dispensando de IV inch lagana in diffusione, oxidatur.

Et vestibulum processus of semiconductor lagam eu eu maxime operuit tres gradus: (fronte scaena) Chip vestibulum (medii scaena) chip vestibulum (tergum scaena) packaging et temptationis. (Fronte scaena) et chip vestibulum processus maxime includit: trahens unum crystallis, molere exteriori circulos, slicing, chamfering, molere et politura, purgatio et temptationis; (Medio scaena) Wafer chip vestibulum maxime includit: oxidatio, diffusio et alias calor treatments, tenuis film depositione (CVD, PVD), metallzation, etching, Ion implantationem, metallzation, etching, Ion implantationem, metallzation, et inlustribus, Ion implantationem, metallzation, et Lithout, Ion implantationem, et metallzation, metallum et poliendos, et metallzation, metallum, et politionem, et metallzation, metallum et poliendos, et metallzation, metallum et politionem, et metallzation, metallum, et Polishing, et testis; (Back scaena) packaging et probatio maxime involves laganum chip secans, filum vinculum, plastic obsignationem, testis, etc. totius semiconductor industria cathal includit IC consilio, IC vestibulum et IC packaging et testis IC et IC packaging et testis. Et Key Processus processus et apparatu involved includit: Lithologs, Etching, Ion implantationem, tenuis film depositione, chemica mechanica polising, princeps temperatus calor curatio, packaging, magno temperatus calor curatio, packaging, magno temperatus calor curatio, packaging, magno temperatus calor curatio, packaging, magno temperatus calor curatio, packaging, Testing, etc.

In the process of semiconductor chip manufacturing, the six important processes of high-temperature heat treatment, deposition (CVD, PVD), lithography, etching, ion implantation, and chemical mechanical polishing (CMP) require not only cutting-edge equipment, but also a large number of high-performance precision ceramic components in these equipment, including electrostatic chucks, vacuum suction cups, Heaters, transferre arma, focusing annulos, nozzles, workbenches, cavum liners, depositionem annulos, bases, lagana laminis, camino, et cavis, etc.

Quisque IV-inch Sic navi subit stricte qualitas imperium, inter dimensional inspectionem, planities mensurae et scelerisque stabilitatem temptationis. Superficiem metam et socors geometria potest esse tailored ut mos cubits. Ad libitum coatings et polymita potest adhuc augendae chemical resistentia aut minimize Micro-particula retention pro ultra-tanchroom applications.

Cum praecisione, puritate et diuturnitatem sunt critica, nostri IV-inchSICNavis providere superior solutio pro Advanced Semiconductor processus. Speres nostri peritia et materiale excellentia ad augendae vestri processus perficientur et cede.