- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

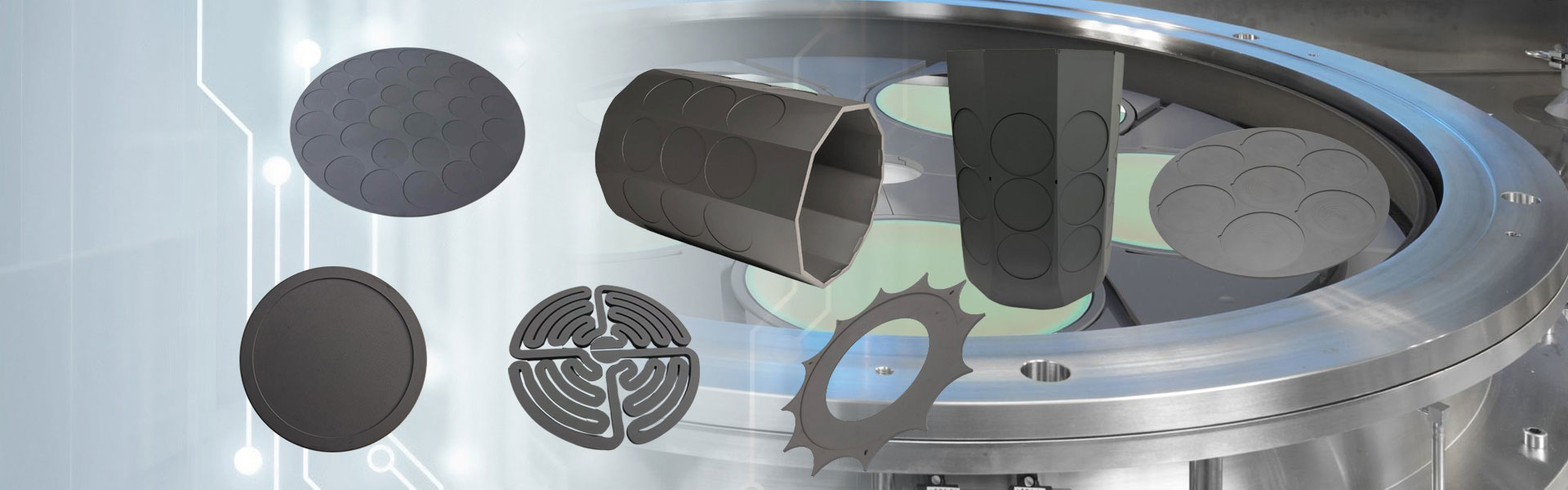

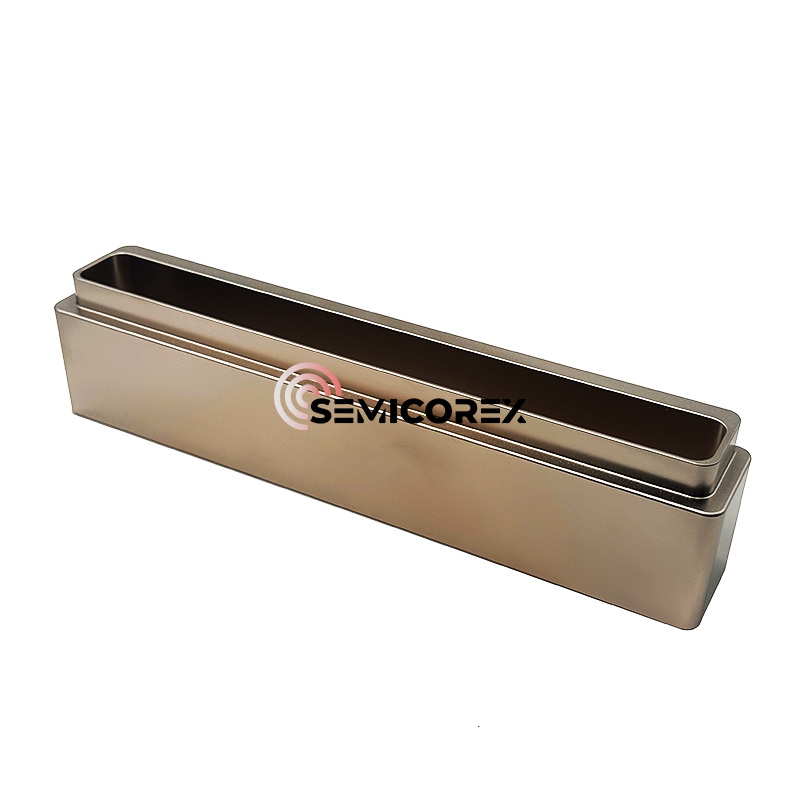

Silicon Carbide Wafer cymba

Semicorex fabrum semiconductor-gradus ceramicorum tuorum OEM instrumenta fabricandi semi- laganum tractantem componunt. Nostra Silicon Carbide Wafer cymba bonum pretium commodum habet et multas mercatus Europae et Americanae operit. Expectamus ad longum tempus socium in Sinis fieri.

Mitte Inquisitionem

Semicorex Siliconis Carbide Wafer cymba, altam puritatem (usque ad 99.99%), optimum plasma resistentiae et resistentiae caloris, et particulae strictae occurrentiae, in instrumentorum instrumentorum processui semiconductore adhibitis, inter componentibus structuralibus et instrumentis utitur.

Apud Semicorex nos intendunt ut summus qualitas, sumptus efficens cymba Silicon Carbide Wafer, prioritize satisfactio emptoris et solutiones sumptus efficaces praebeamus. Expectamus ad longum tempus socium fieri, praecipuos qualitas products et eximias servitutis emptores tradens.

Contactus nos hodie ut plura de nostro Silicon Carbide Wafer cymba discamus.

Parametri Silicon Carbide Wafer cymba

|

Technical Properties |

||||

|

Index |

Unitas |

Precium |

||

|

Materia Nomen |

Silicon Carbide reactionem Sintered |

Silicon Carbide |

Silicon Carbide recrystallized |

|

|

Compositio |

RBSiC |

SSiC |

R-SiC |

|

|

Mole densitas |

g/cm3 |

3 |

3.15 ± 0.03 |

2.60-2.70 |

|

Flexurae Fortitudo |

MPa (kpsi) |

338(49). |

380(55) ; |

80-90 (20°C) 90-100(1400°C) |

|

Compressive fortitudo |

MPa (kpsi) |

1120 (158) |

3970 (560) |

> 600 |

|

duritia |

Button |

2700 |

2800 |

/ |

|

Fractio Tenacity |

MPa m1/2 |

4.5 |

4 |

/ |

|

Scelerisque Conductivity |

W/m.k |

95 |

120 |

23 |

|

Coefficiens Scelerisque Expansion |

10-6.1/°C |

5 |

4 |

4.7 |

|

Imprimis Caloris |

Joule/g 0k |

0.8 |

0.67 |

/ |

|

Max temperatus in aere |

℃ |

1200 |

1500 |

1600 |

|

Modulus elasticus |

Gpa |

360 |

410 |

240 |

Discrimen inter SSiC et RBSiC;

1. Processus Sintering differt. RBSiC est liberum Si in carbidam Pii in temperatura infiltrare, SSiC reformatione naturali in 2100 graduum formatur.

2. SSiC superficiem leviorem, densitatem altiorem et vires superiores habent, ob signationes aliquas strictiores superficiei requisitas, SSiC melius erit.

3. Diversus usus temporis sub diversis PH et temperatus, SSiC est longior quam RBSiC

Features of Silicon Carbide Wafer cymba

Superior calor resistentia & scelerisque uniformitatem

SiC crystal obductis ad superficiem levem

Princeps firmitatem contra chemica purgatio

Materia designata est ut rimas et delaminationes non fiant.

![]()

![]()

![]()